The ThreadBoard: Designing an E-Textile Rapid Prototyping Board

Chris Hill*, Michael Schneider*, Ann Eisenberg, Mark D Gross

(The first two authors equally contributed to the publication)

Abstract:

E-textiles, which embed circuitry into textile fabrics, blend art and creative expression with engineering, making it a popular choice for STEAM classrooms. Currently, e-textile development relies on tools intended for traditional embedded systems, which utilize printed circuit boards and insulated wires. These tools do not translate well to e-textiles, which utilize fabric and uninsulated conductive thread. This mismatch of tools and materials can lead to an overly complicated development process for novices. In particular, rapid prototyping tools for traditional embedded systems are poorly matched for e-textile prototyping. This paper presents the ThreadBoard, a tool that supports rapid prototyping of e-textile circuits. With rapid prototyping, students can test circuit designs and identify circuitry errors prior to their sewn project. We present the design process used to iteratively create the ThreadBoard’s layout, with the goal of improving its usability for e-textile creators.

The ThreadBoard:

The ThreadBoard platform we have been developing is useful and appropriate for beginning e-textile makers of any age. Our ThreadBoard provides a layout of magnetic connectors that holds circuit components and conductive thread in place. This allows makers to rapidly prototype e-textile projects by quickly exploring and investigating different e-textile circuit designs, testing components, and finding and fixing bugs before committing to stitching the circuit into a fabric substrate.

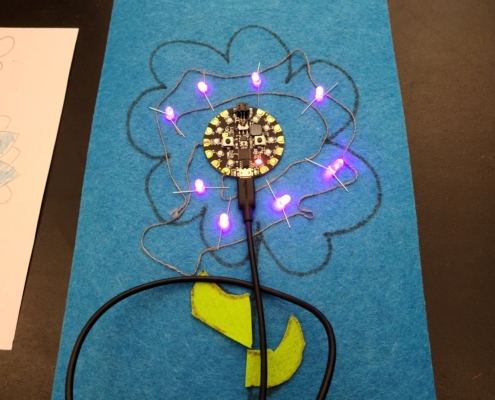

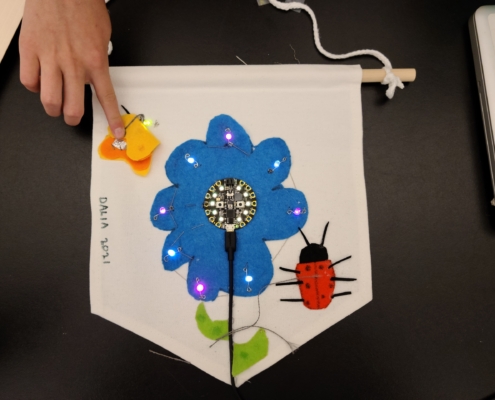

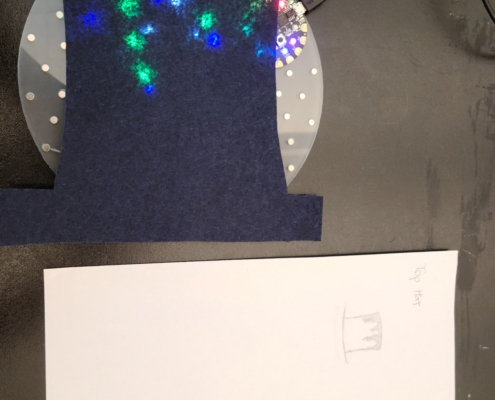

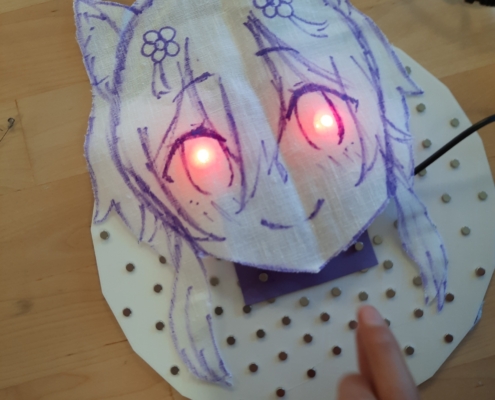

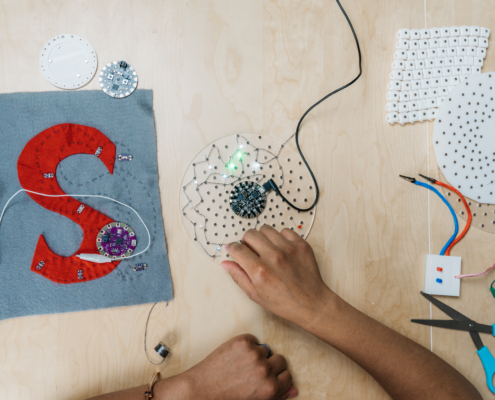

Example Project:

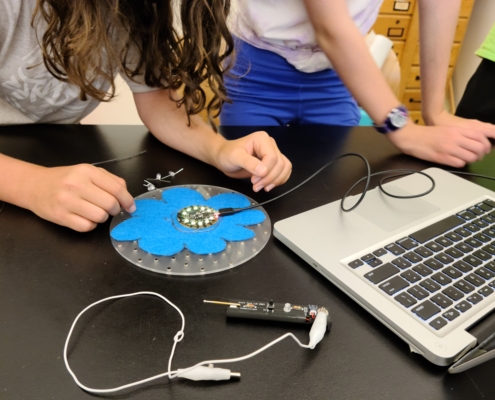

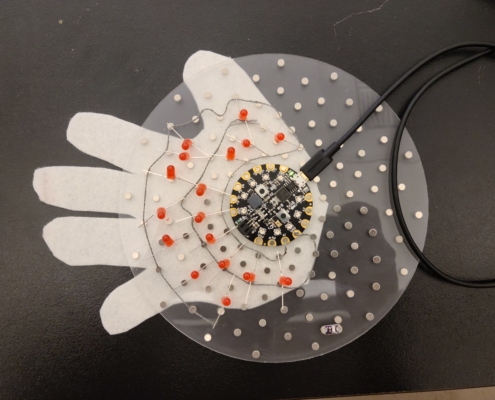

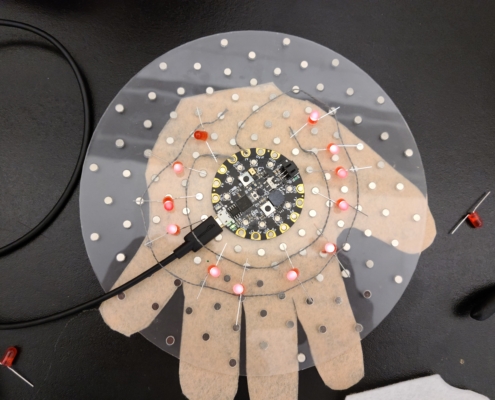

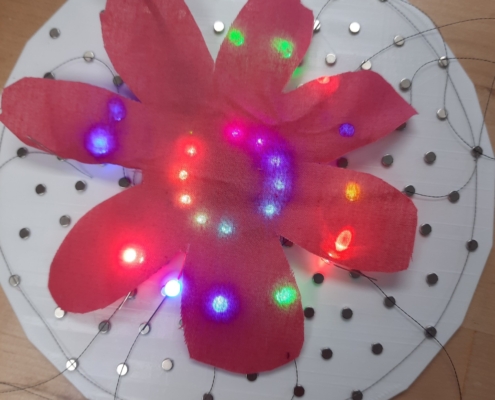

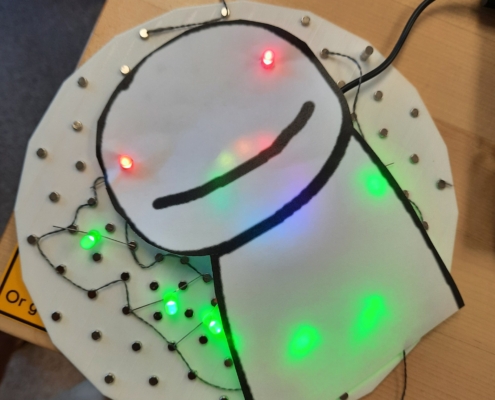

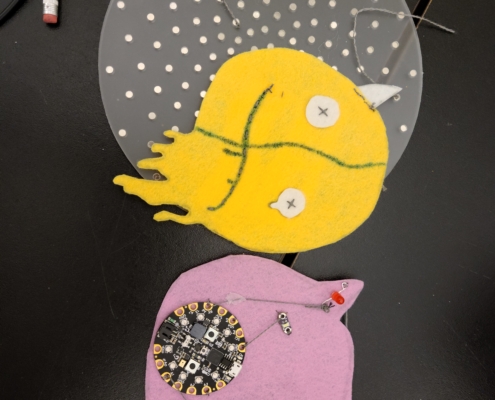

Student Example Projects:

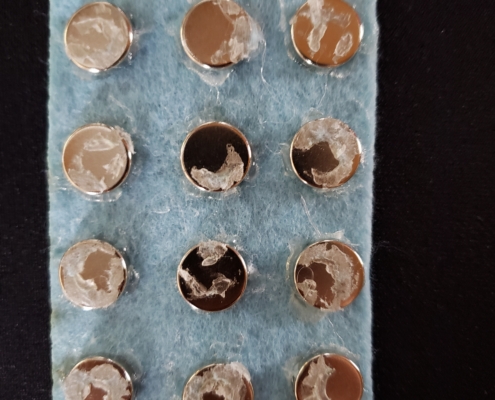

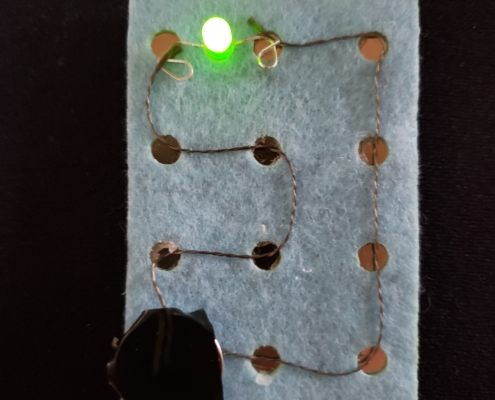

Original ThreadBoard Prototype:

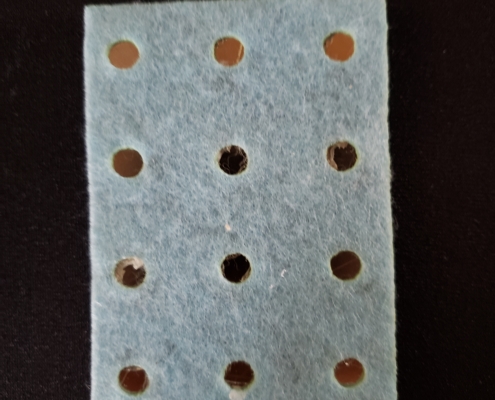

The first ThreadBoard (V1) was designed for a coin cell battery, which allows users to make basic circuit designs that support a single actuator. The design’s stiff felt, to which the magnets were glued, could bend and fold around other objects. This allowed it to attach to flat or slightly curved metallic surfaces (e.g., a refrigerator or a water bottle) or to a metallic pin on the wearer’s clothing. ThreadBoard V1 demonstrated that e-textile components—such as stainless steel conductive thread and LEDs—can be held in place by a magnet, enabling the construction of simple e-textile circuits. However, ThreadBoard V1’s size restricted creators to a small work area and did not allow for more complex projects, such as those that require a microcontroller.

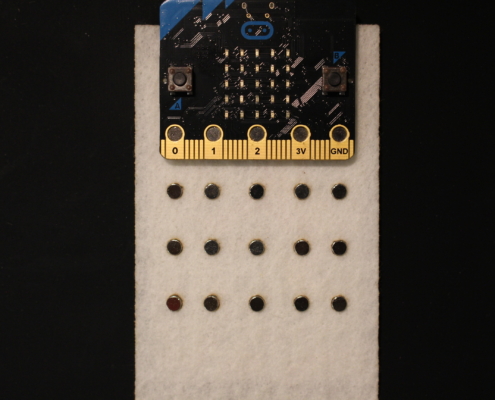

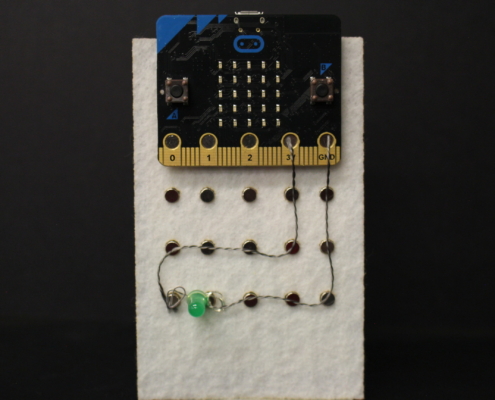

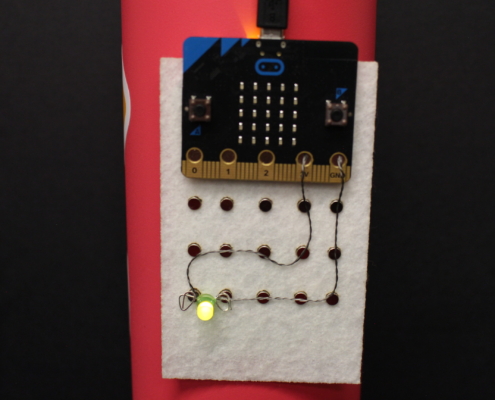

The ThreadBoard’s Second Prototype:

The second ThreadBoard (V2), changed the layout of the magnets to accommodate a BBC micro:bit. The magnets are arranged in columns aligned with the micro:bit’s GPIO (0,1,2). power (3v), and ground (GND) pins.

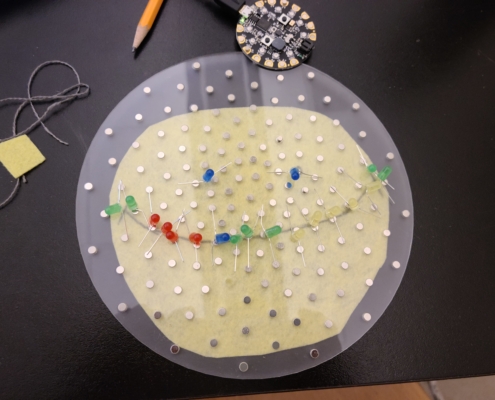

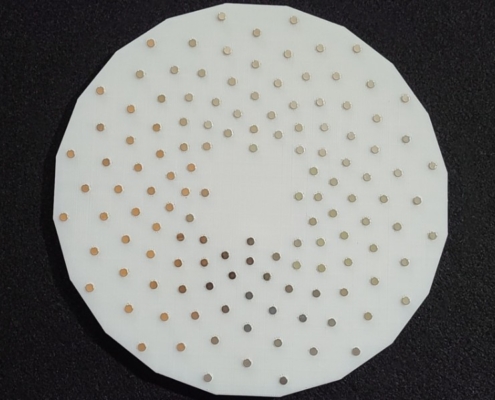

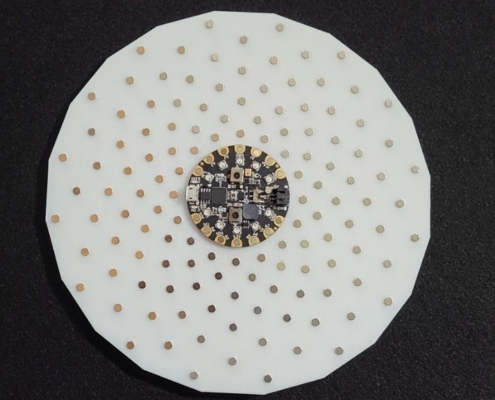

The Current ThreadBoard:

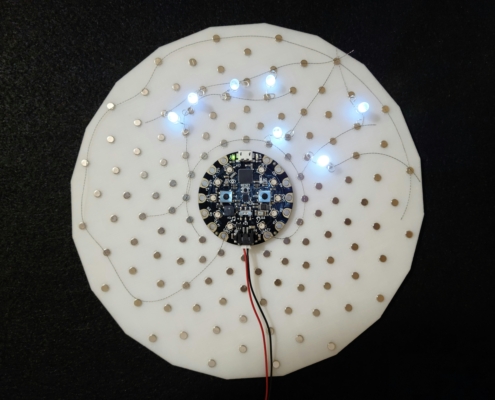

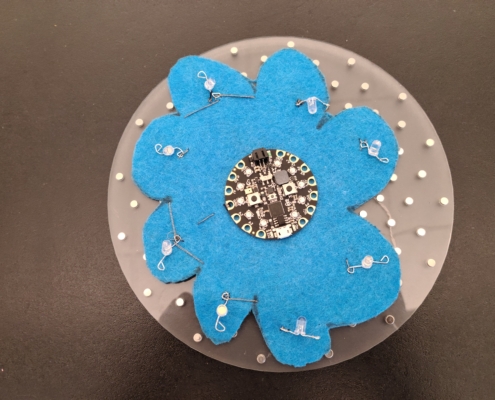

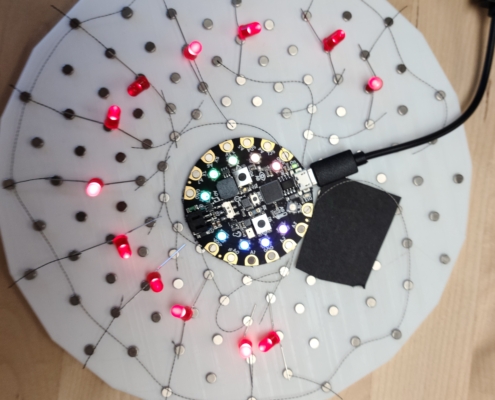

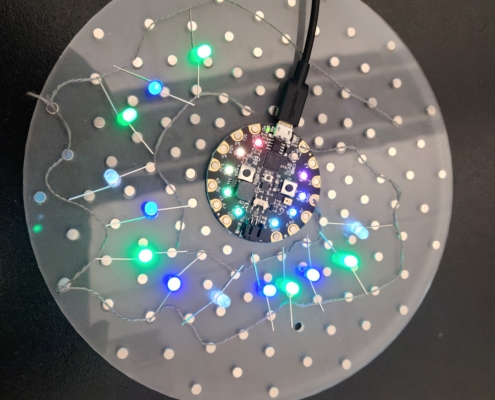

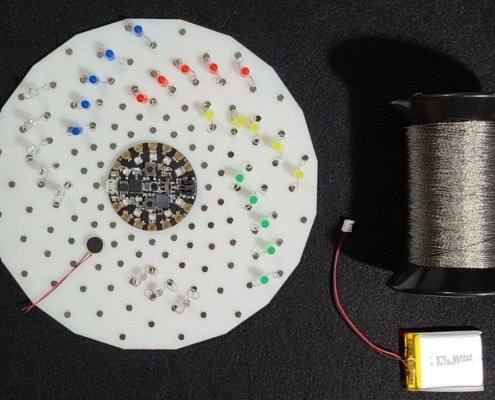

The current ThreadBoard layout is designed to support e-textile-specific microcontrollers like the LilyPad Arduino and Adafruit Circuit Playground (Figure 4, left). We also provided a larger area for making circuitry with the microcontroller placed at the center for aesthetic reasons, for example, and this suggested arranging the magnets in the floral disk pattern (Figure 4, right). This version of the ThreadBoard is sized at 192.9 x 190.3 x 3.0 mm with 128 holes for the magnets.

(Photo credit to Elliot Whitehead)

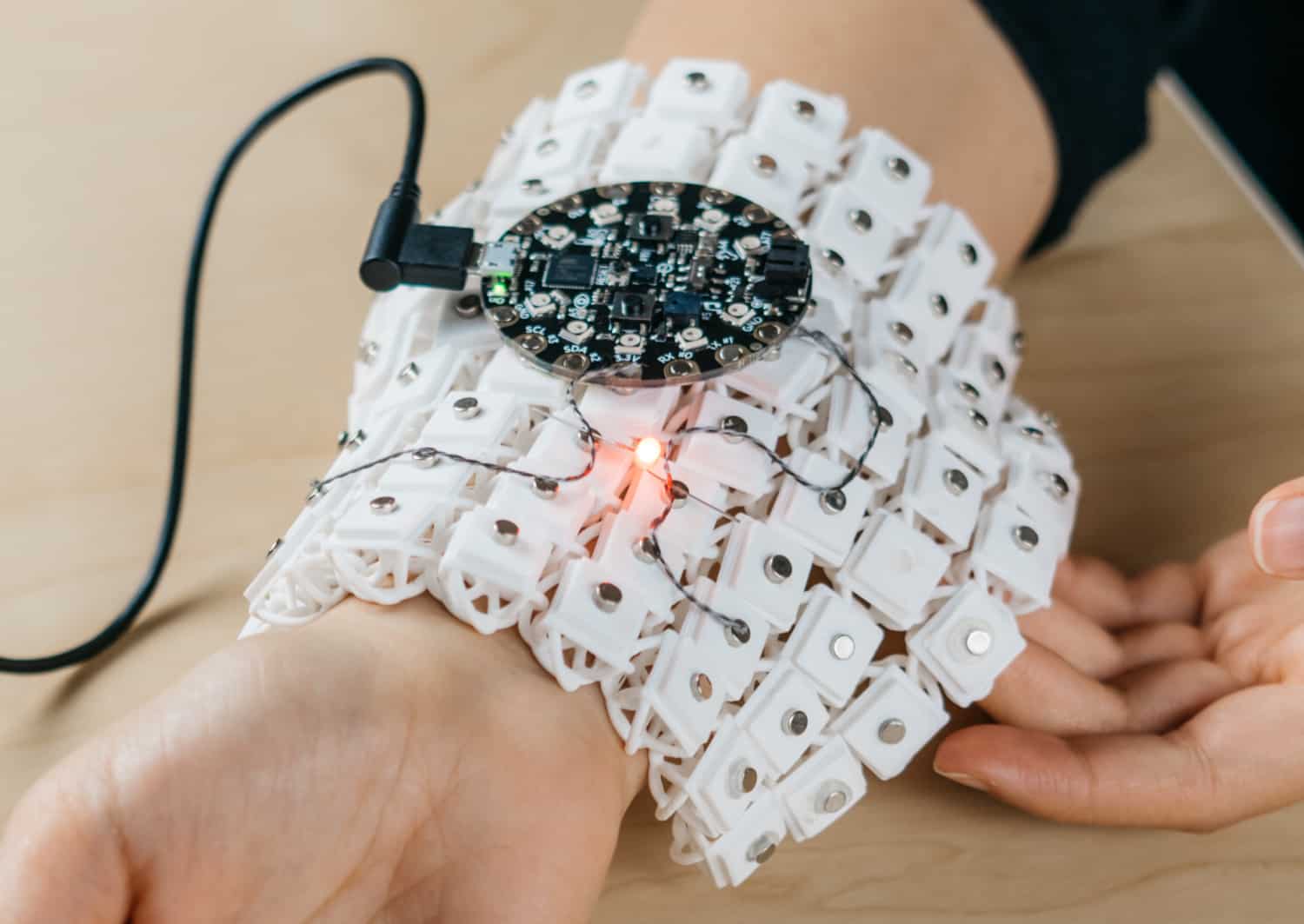

The Next ThreadBoard:

The current ThreadBoard is a rigid flat plate. We plan to modify this design into a three-dimensional prototyping device, which will more closely take the forms of many e-textile projects. We are beginning to work with a flexible three-dimensional mesh that can mold into a surface that mirrors the geometry of the target project, whether it is a stuffed animal, an article of clothing, or other fabric substrate.